APPLICATION OF Smartindale Martindale Abrasion & Pilling Tester

The materials that Smartindale Martindale Abrasion & Pilling Tester can test are cotton, hemp, silk woven fabrics and other textiles, membrane materials, knitted fabrics, woolen textiles, artificial leather, synthetic leather, gloves, labor protection materials, etc.

Smart instrument

This Smartindale Martindale Abrasion & Pilling Tester can be connected through Wi-Fi with SmarTexLab App installed in the smart phones, then you can set parameters, monitor the test status, and receive equipment warning reminders, replenishment reminders, etc., and share the Martindale Abrasion & Pilling test results with one click.

Calibration-free

The dual action of servo driver and position sensor allows the Smartindale Martindale Abrasion & Pilling Tester to achieve accurate testing continuously.

The original digital drive achieves a higher level of test accuracy.

Smartindale Martindale Abrasion & Pilling Tester replaces the traditional analog drive with a digital drive, it is an exclusive innovation in the industry with the combination of dual servo motors, micro controller, embedded, mathematical model, point-to-point drive, etc., and it can directly generated LISSAJOUS by single point, with higher precision and reliability of the Martindale Tester.

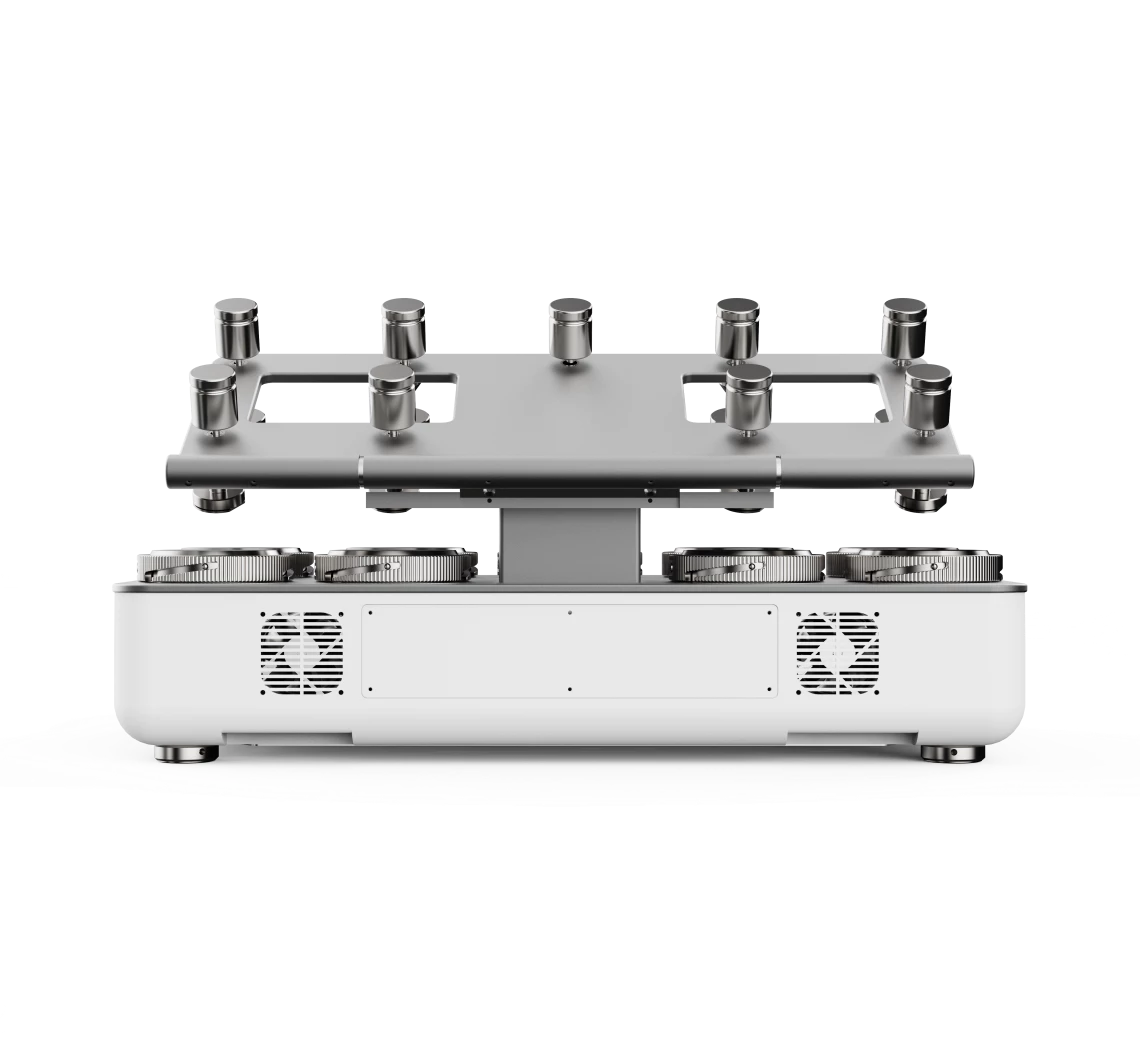

One-click to shift the testing modes

Compared to conventional Martindale abrasion tester, with the Smartindale, you don’t need to remove the top plate and change the pins, just click one key of the screen to switch the testing modes from abrasion to pilling (e.g. Abrasion, Pilling, Line).

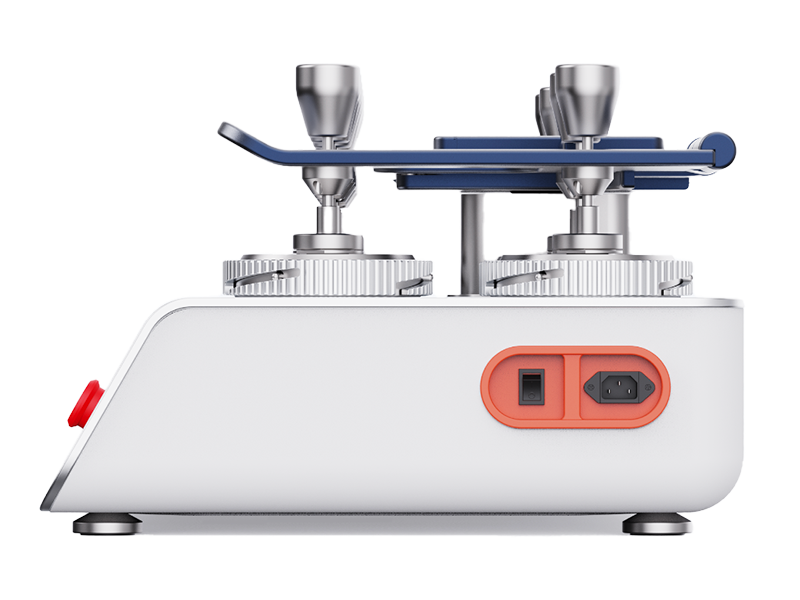

Ergonomic design

The moving guide plate of this Martindale test machine can be operated by one hand and automatically close, with anti-collision function, more friendly to testers.

Reliable martindale test

The excellent manufacturing accuracy of machining and assembly makes the abrading table and specimen holder are highly parallel to each other during running, and the specimen holder has a small run out to the surface of the abrading table (less than 0.05mm), which is more conducive to obtaining reliable Martindale test results.

OUR BROCHURE

OUR CATALOG

mARTINDALE ABRASION TEST STANDARDS

ISO 12945-2-2020

ISO12947-2-2016

ISO12947-1-1998

ISO12947-3-1998

ISO12947-4-1998

GB/T 21196.1-2007

GB/T 21196.2-2007

GB/T 21196.3-2007

GB/T 21196.4-2007

GB/T 4802.2-2008

ASTM D4970/4970M-22

ASTM D4966-22

BS EN 530-2010

Optional standards

BS EN 388-2016+A1-2018 SATRATM31 A/B PUMA

BS EN 16094-2012 ISO 20344-2021 Item 6.12

BS EN 13520-2002 ISO 5470-2-2021

TECHNICAL DATA

Abrasion test

(198±2)g

Specimen clamps weight

60.58±0.5mm

Maximum travel

Pilling test

0.2%~100%FS

Test force range

7.5mm±0.1mm

Friction head and upper plate spacing

24±0.5mm

Maximum travel

INSTALLATION

220v/110v 50/60Hz

AC230V 50/60Hz 3A

Power Supply

| Smartindale 4 | 65kg | 650*510*280mm |

| Smartindale 6 | 75kg | 650*510*280mm |

| Smartindale 9 | 90kg | 510*850*300mm |

Climatic Environment

The unit is intended to operate within the following conditions

25+/-5 deg Celsius Temperature | 30-65 RH % Humidity |

<2000m above sea level Altitude | -25-+ deg Celsius.Storage |

For more information,please check from the Download Brochure

Accessories of Martindale Abrasion and Pilling Tester

Accessories

Fuse tube 2pcs

Foam wool 9 pcs Φ38 mm

Wool felt 18 pcs Φ90 mm,Φ140 mm

Wool abrasive 9 pcs Φ140 mm

Sampling plate 3 pcs Φ38 mm,Φ90 mm,Φ140 mm

Sampler 1 pc for pilling test

Sampler 1 pc for abrasion resistance test

Press 1 pc Φ126mm,2.5kg

Fixture1 9 sets for pilling test

Fixture 2 9 sets for abrasion test

Weight 1 9 sets 12Kpa

Weight 2 9 sets 9Kpa

Rubber ring 9 pcs for pilling test

Test pen 1pc

Connection shaft 9pcs for pilling test

Connection shaft 9pcs for abrasion test

Stainless steel ring 9pcs 260g

Optional Accessories

EMPA990 rating chart card 1 set knitted + Woven

SM50 rating chart card 1 set IWS + ASTM

SM25 abrasion-resistant wool cloth 1 pack 1.6 X 5m/pack

SM26 woven wool felt 1 box 24 pcs/box Φ140mm

SM26 woven wool felt 1 box 24 pcs/box Φ90 mm

SM28 polyurethane ether foam 1box 250 X 200mm/pc, 25pcs/box

GET A QUOTE

Following the martindale abrasion tester working principle, the test involves placing a fabric specimen in the clamp of the machine. The specimen will then be abraded in a standard Lissajous figure against an abradant, such as leather. As the tester operates on this rubbing motion, it simulates real-world abrasive forces like fabric contacting other surfaces through daily use and cleaning. Once the required abrasion cycles are reached according to test standards or the martindale abrasion tester protocol, the specimen will be evaluated. If breakage occurs, the cycle number is recorded to calculate the abrasion resistance index. Alternatively, a visual assessment of the fabric pilling and wear rate can be made to determine its durability performance rating.

- Test piece preparation

- Test piece selection

- Test placement

- Placement of wool felt and abradant

- Pressing the abradant on the pressure head

Before calibration, it is necessary to confirm that there are no defects in appearance and electromechanical functions that affect the calibration measurement characteristics……

- Must be regular external cleaning of the instrument as well as cleaning, to ensure the cleanliness of the test instrument

- Regular inspection of the test instrument to see if there are any abnormalities;

- The use of personnel in the process, should be used in accordance with the correct method of use, not illegal use, so as not to damage the instrument, resulting in shortening the life of the instrument;

- After the test instrument is finished, the personnel should put the instrument away and clean it accordingly to ensure the cleanliness of the instrument.

- In the case of not using the instrument, the power of the instrument should be turned off, and continue to keep the instrument clean.

_1_.webp)