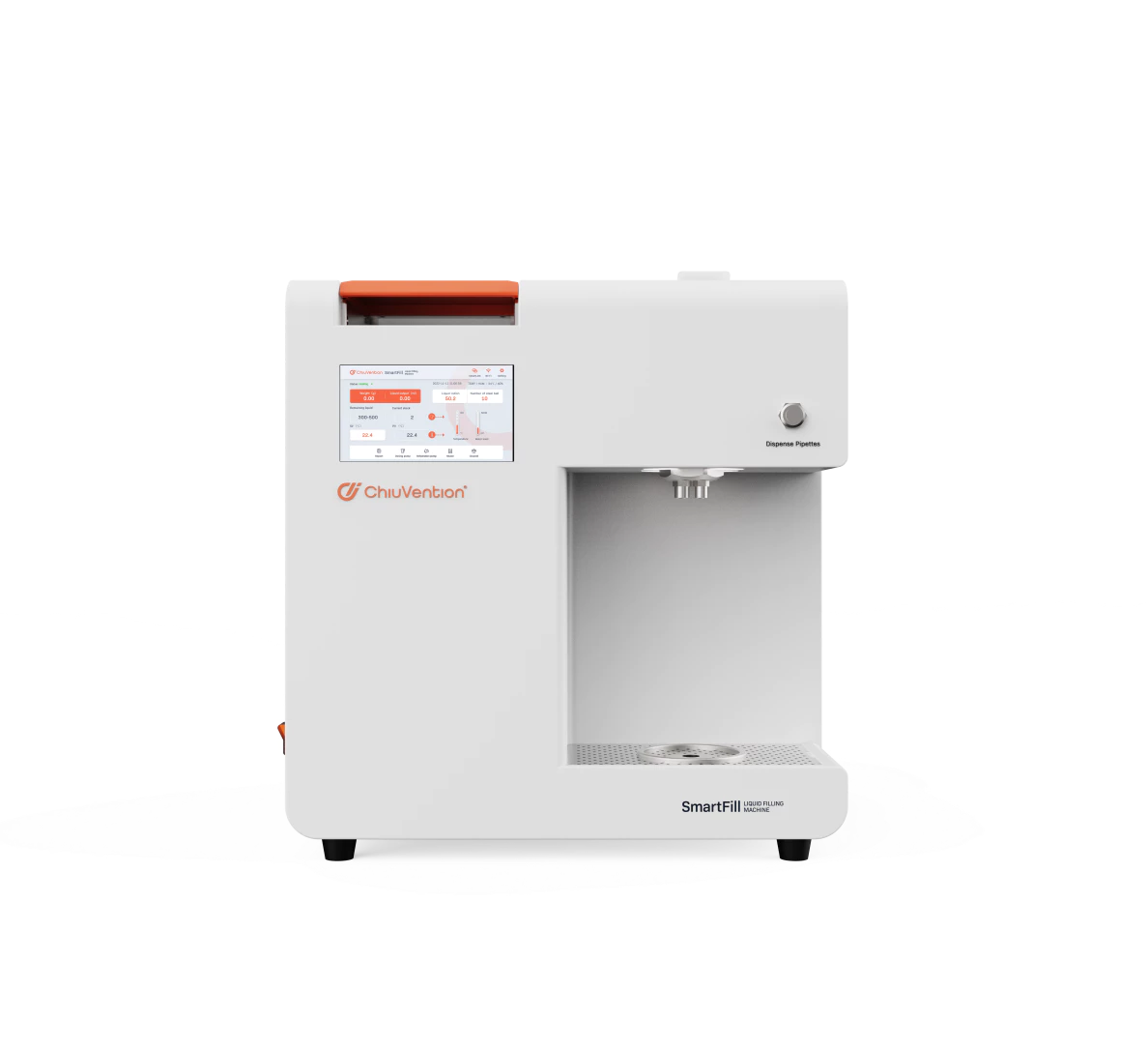

Smart instrument

This drying rate tester can be networked with smartphone, so you can set parameters and monitor test status remotely, also directly get test results and equipment warning alerts, etc.; Besides, you can share the test results with others.

Efficient and convenient, and more reliable test

With high precision temperature sensor, wind speed sensor and precision drip device, you can complete the test of drying rate quickly in 10 minutes.

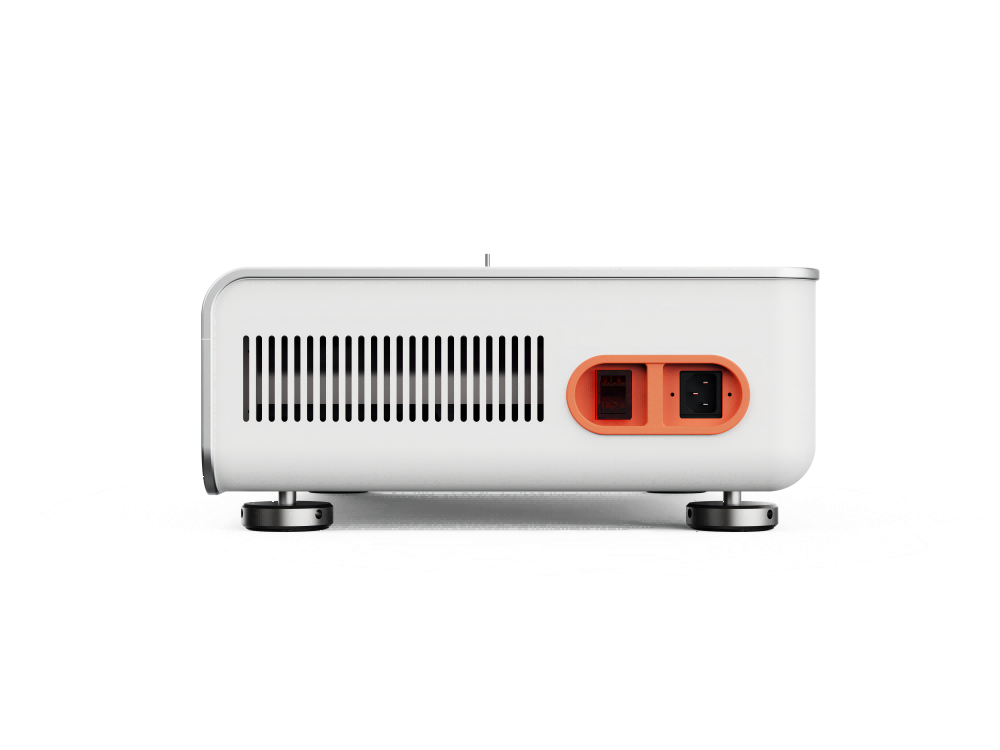

The SmartDry Drying Analyzer specially designed parallel cross-flow fan makes the wind speed more uniform and smooth, which can restore the actual evaporation process and make the test results more reliable.

Simple and easy to use

The whole test process will be displayed on the screen and present it as a clear data curve.

Precise appearance design, aluminum alloy hard oxidation surface, durable and easy to clean; seven-inch color touch screen is easy to use.

The Specification of SmartDry Dry Rate Tester

Fan:

can produce airflow of 0.5-3.5m/s

Heater plate: 305mm x 305mm±1mm

Soft heating plate: 305mm x 305mm±1mm

Heat-insulating cork board: 305mm x 305mm±1mm

Metal pressure bar: 150mm x 40mmx2mm±1mm

The Heating temperature:

25-40℃±0.5℃(with overheat protection)

Test Accuracy: 0.5-3.5m/s±0.1m/s

Infrared temperature sensor: 15-50℃±0.1°C

Drip accuracy: 0.05-1.0ml ± 0.003ml

1.0-4.5ml ± 0.01ml

Accessories

Fuse 2pcs

Sampling plate 1 pc 150mm*150mm

Water bottle 1 pc 60mL

Standard

AATCC201

Power AC100-245V 50/60Hz 3A

Weight 20kg

Dimension 400*590*180 mm (D*W*H)

Frequently Asked Queastions

The drying rate testing machine is used to measure how quickly coatings, paints, inks and other materials dry. It objectively tests the drying time under controlled conditions.

It typically works by applying a thin, even layer of the material to be tested onto a non-absorbent surface like glass or metal. The material is then exposed to controlled temperature and humidity inside the tester. Sensors periodically measure aspects like hardness, gloss or tackiness to determine when the material is considered dry.

Common materials tested include solvent-based and water-based paints, varnishes, lacquers, inks, coatings, adhesives and more. Essentially any liquid or suspension-based product that needs to dry can be analyzed.

Typical controls include temperature, humidity, air flow/circulation, material application thickness and test interval times. More advanced models allow customizing multiple parameters to mimic real-world drying conditions.

Lab-grade testers can measure drying to within just a few minutes. Accuracy depends on the specific model and sensors, with some claiming accuracies of just 1-2 minutes depending on the test parameters and material tested.

The objective data on how formulations dry under controlled conditions helps developers optimize variables like resin content, solvents, additives and more to achieve optimal drying performance traits.

_1_.webp)