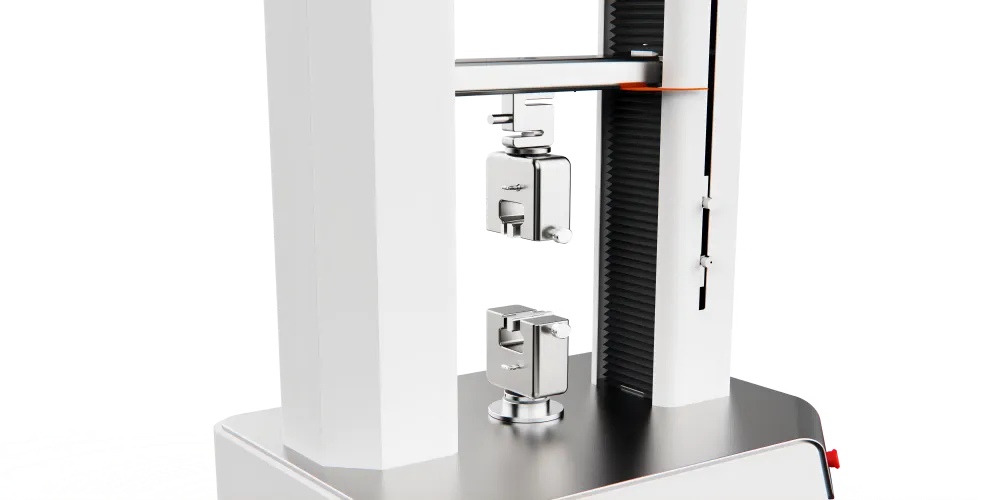

Higher Testing Accuracy and Reliability

The tensile strength tester’s AC servo drive and ball screw system provide stable pulling force with 1% force accuracy

Ensures reliable and repeatable test results from the tensile strength tester meeting international standards

User-Friendly Design

The tensile strength tester’s ergonomic trapezoidal base and rounded edges for stable operation

Intuitive interface in the tensile strength tester optimized for ease of use and efficiency

Safety Assured

The tensile strength tester’s intelligent displacement, torque and overload alarms protect operator and samples

Emergency stop and travel limiting devices in the tensile strength tester enhance safety during testing

Customization Capabilities

The tensile strength tester offers optional load cell capacities from 5kN to 20kN for varied testing needs

Choice of basic or advanced software for the tensile strength tester

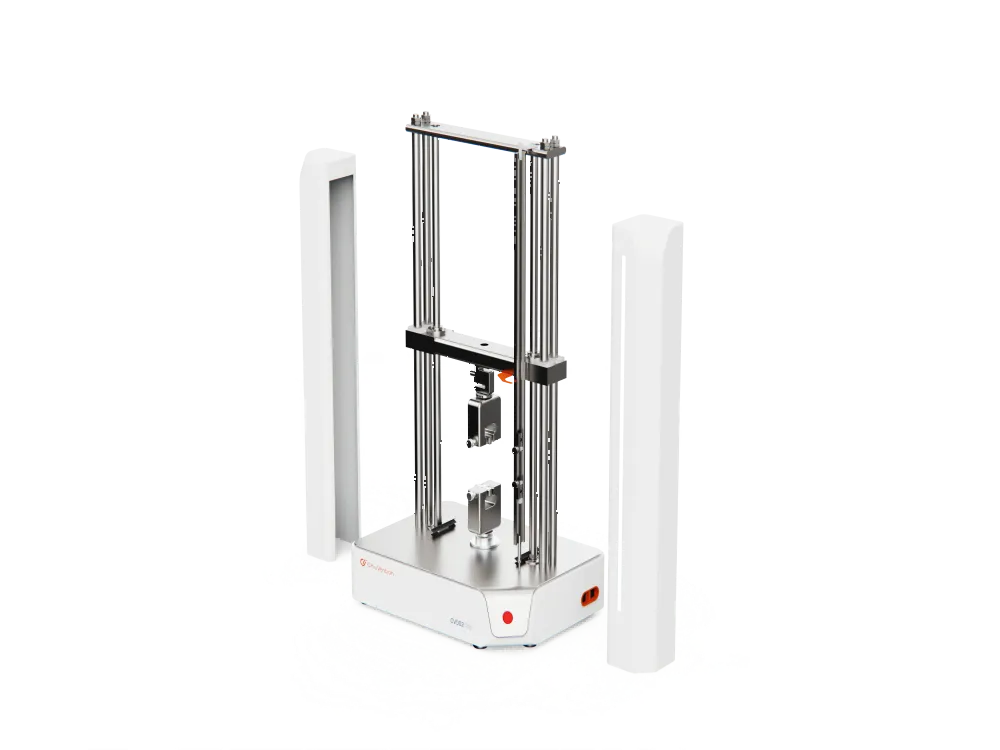

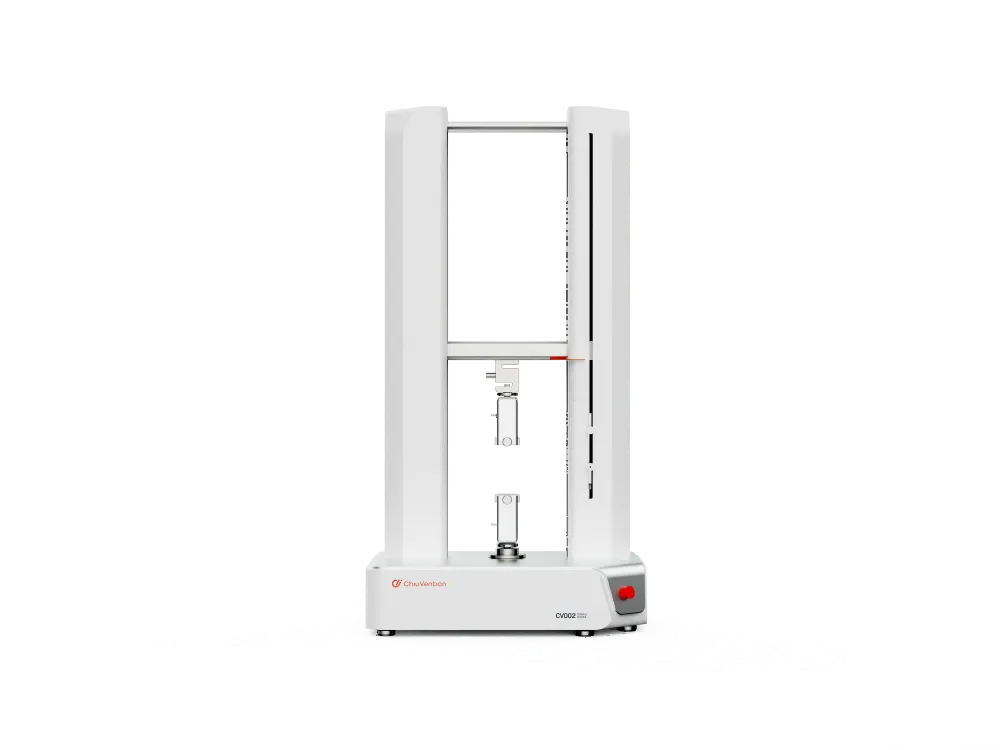

The crystallization of technology and humanity

The appearance is full of technology sense, rounded line processing, more warm feeling, trapezoidal base design, more stable.

Powerful Software

The test software can be applied to different languages, and can present the displacement, maximum force, elongation, stress, maximum stress, bending stress, speed and other test results. That is ,getting more comprehensive test indicators.

Strict Inspection, High Quality

30 days of continuous testing before leaving the factory, simulated transport testing, to ensure that each unit of Tensile Strength Tester CV002 can meet customers’ needs.

The Specification of SmartPull Tensile Strength Tester

Testing capacity: 1000 kg

Test level: class1

Max Travel: 900mm (without fixture)

Travel accuracy: ±0.5%

Travel speed: 1mm/min ~500mm/min

Speed accuracy: speed <10mm/min, within ±1% of the set value

Speed ≥10mm/min, within ±0.2% of the set value

Test force range: 0.2% ~ 100%FS

Test force value accuracy: ±1%

Range of constant rate control: 0.5%~100FS

Fixture of Tensile Strength Testing Machine

Standard fixture and corresponding standards:

Manual stretching fixture should be equipped with: 25x25mm, 25x50mm, 25x75mm clips

ISO 9073-3 ISO 13934-1 ISO 13934-2

ISO 13935-1 ISO 13935-2 ASTM D5034

ASTM D5035

Optional fixture and standards

The Pneumatic tension fixture & foot switch are equipped with:25x25mm,25x50mm,25x75mm clips

25x75mm clamp(Optional 100mm jaws)

U-shaped Fixture ASTM D4964

Yarn Fixture ISO2062

Bursting Fixture ASTM D6797 FZ/T 01030 GB/T 19976

Leather Tearing Fixture ISO 3377-2

Tensile Test Standards of the optional tension fixture

ISO 9073-4 ( require 25x100mm clips) ISO 3377-1

ISO 13936-1 ISO 13936-2

ISO 13937-2 ISO 13937-3 ISO 13937-4

ISO 20932-1 (need to match the linear fixture, the type of fixtures may need to be changed )

ISO 4674-1 GB/T 3917.3 GB/T 3917.5 GB/T 3923.1

75mm tension fixture jaw mounting block (optional 100mm jaw,quantity 0)

Computer Configuration of Tensile Tester (Optional)

CPU for the Intel Celeron (Celeron) 2GHz or more CPU

Memory at least 512MB, recommended more than 1GB

Hard disk space above 2GB

Display resolution of 1024 × 768 or more.

Printer compatible with the operating system (if output reports are required)

The applicable operating system for Microsoft’s Windows XP, Windows 7, Windows 8, Windows 10

If need to output the report in Word&Excel format, you should install Microsoft’s Microsoft Office 2003, 2007, and 2010 versions of the software.

Accessories

Standard accessories: manual stretching jig, 25x25mm jaws,

25x50mm jaws, 25x75mm jaws, sample template, pins, manual,

power cord, communication cable, control panel, fuse

Optional accessories

pneumatic stretching jig, foot switch, bursting jig

Power 230 V 50/60 Hz 5A

Weight 160kg

Dimension 600*830*1730 mm (D*W*H)

Frequently Asked Queastions

Tensile Strength Tester, we can also call a tensile testing machine, fabric strength tester. Its main purpose is to test the tensile strength of textile materials.

Tensile strength refers to the maximum stress that a material can withstand while being stretched or pulled before necking or breaking. For textile products, tensile strength directly affects its lifespan and quality.

With this tensile strength testing equipment, users can perform tensile tests on textile fabrics or fibers to measure their strength under different levels of stretching. The tester will apply uniform stretching to the test sample while recording tensile values, in order to draw the tensile strength curve.

Through tensile strength testing, the quality of textile raw materials or finished products can be evaluated, and reference data provided for subsequent production. This is highly significant for improving the level of products in textile enterprises.

Here are some common applications of a fabric tensile strength tester:

- Quality control testing of woven, knitted or nonwoven fabrics: Test fabric strength at various stages of production to ensure it meets specification requirements.

- Material development: Textile manufacturers use it to test new materials and blends during product development.

- Fiber and yarn testing: It can test individual fibers, filaments or entire yarns to determine tensile properties.

- Raw material inspection: Incoming raw materials like fibers, yarns and fabrics are tested on receipt to verify strength matches paperwork.

- Manufacturing process control: Fabric strength is monitored through processes like weaving, knitting, dyeing/finishing to detect issues.

- Wear testing: Simulate effects of wear and laundering by repeated tensile tests to rate fabric durability.

- Finished product inspection: Final textile products are tested before release to avoid weakness failures in use.

- Military/industrial fabric certification: Strong fabrics for protective clothing, equipment, tarps etc. require certification.

- Forensics: Determine if fabric failure was product fault or caused by external factors in liability investigations.

- Research and development: Universities and textile labs use it for fabric improvement studies.

Here are some key features to consider when selecting a tensile strength tester:

- Load capacity – Max load it can test depends on material strength e.g. 5kN, 20kN, 50kN.

- Grips/jaws – Suitable for thin films or bulky materials like clothing. Pneumatic or manual operation.

- Speed control – Static or dynamic testing capabilities and range of testing speeds.

- Data acquisition rate – Consider sampling rate needed like 500Hz for high-speed tests.

- Measurements – Can it measure load, elongation, stress-strain curves, tear strength etc?

- Software – Ability to program test routines, export data formats for analysis.

- Standards – Verify it complies with standards like ASTM, ISO, JIS for accuracy andValidity.

- Automation – Options like auto-calibration, sample loading/unloading if used in production.

- User interface – Touch screen with intuitive controls for ease of use.

- Safety features – Overload protection, emergency stop buttons, protective covers.

- Service & support – Post-sales technical assistance, spare parts availability, calibration packages.

- Cost – Consider purchase cost, operating cost and expected use for budget.

The maximum load capacity of a tensile strength tester can vary depending on the specific model. Here are some typical maximum load capacities seen in commercial tensile strength testers:

- Light duty lab testers: 1 kN to 5 kN

- General purpose testers: 5 kN to 20 kN

- Heavy duty testers: 20 kN to 50 kN

- Very heavy duty testers: Above 50 kN

The maximum load capacity needs to match the intended testing applications. For example:

- Fabric and yarn testing can be done with under 20 kN load cells.

- Fiber testing may only require 1-5 kN loads.

- Rubber, threads and films can be 5-20 kN.

- Steel wire rope and chains require 20-50 kN or higher loads.

Premium models may offer load ranges in the same machine using interchangeable load cells. This provides flexibility for different materials.

Load accuracy is also important, typically within +/-0.5% to 1% of rating. Proper load cell selection ensures test results fall within the rated measurement range.

So in summary, maximum load capacity depends on material strength and tester specifications, ranging from 1 kN for delicate tests to over 50 kN for heavy materials.

The accuracy of a tensile strength tester depends on the specific model, but in general, tensile testers aim to achieve high accuracy levels. Some key points about tensile tester accuracy:

- Load measurement accuracy is typically within ±0.5% to 1% of the rated load capacity of the load cell. For example, a 20 kN load cell would have an accuracy of ±0.1-0.2 kN.

- Displacement/extension accuracy is also very good, often ±0.5% or better of the full scale range.

- High-end systems can achieve even higher accuracy of ±0.25% for load and ±0.1% for displacement.

- Factors like system calibration, load cell type, data collection rate influence the effective accuracy achieved.

- Accuracy is usually specified and guaranteed by manufacturers in technical specifications.

- Industry standards like ASTM D638 prescribe a minimum accuracy level for reported values.

- Calibration is important to maintain the rated level of accuracy over time.

So in summary, a high quality tensile tester today can provide load accuracy within ±0.5-1% and displacement accuracy within ±0.5% depending on specific product capabilities. This level ensures reliable, reproducible test data. Proper use and calibration sustains the rated level of precision.

The typical testing speed range that can be achieved on a tensile strength tester is:

- Low-speed range: 0.1 mm/min to 50 mm/min

This low-speed range is suitable for testing very thin and delicate fabrics or films. It allows gradual application of force to prevent tearing.

- Medium speed range: 50 mm/min to 500 mm/min

Most general-purpose fabric and material testing is conducted within this medium range. It’s fast enough but also prevents sudden failure of samples.

- High-speed range: 500 mm/min to 2000 mm/min

Used for testing plastics, composites, rubber and other tough materials. Also useful for production line quality checks.

- Very high speed: Above 2000 mm/min

Some advanced testers can achieve very high speeds for dynamic impact testing of ballistic materials, aviation composites etc.

The exact speed capabilities depend on the individual tensile tester model. Higher rated loads generally mean more mechanical robustness for high speeds.

Yes, tensile strength testers are versatile machines that can test a wide variety of materials. Some of the common materials that can be tested include:

- Fabrics – Different types of woven, knitted or nonwoven fabrics.

- Yarns – Natural and man-made fibers, filaments, spun yarns, plied yarns.

- Films and thin sheets – Plastic films, foil laminates, paper sheets.

- Rubber and elastomers – Different grades of rubber, seals, o-rings, silicones.

- Composites – Fiberglass, carbon fiber, Kevlar composites, laminates.

- Plastics – Different polymer samples, injection molded parts.

- Metals – Wires, cables, thin metal sheets, aluminum, mild steel.

- Non-metals – Ceramics, concrete, wood, cork, leather, sealants.

- Biological tissues – Tendons, cartilage, skin tissues from animals/humans.

- Paper and board – Cardboards, corrugated boxes, tissues.

Adjustable parameters like grips, speed and data acquisition allow testing various sample types from thin films to bulk materials and fine wires to heavy cables.

Options like cryogenicgrips further enhance versatility for low temperature testing of polymers, composites etc.

So in summary, a tensile tester is a versatile materials characterization tool for a wide cross-section of industries and research applications. Proper adaption lets it test almost any material.

Tensile strength testers are commonly used to conduct tensile tests according to various ASTM international standards. Here are some of the key ASTM standards related to tensile testing:

- ASTM D638 – Standard test method for tensile properties of plastics. Most widely used for testing plastics and polymers.

- ASTM D882 – Standard test method for tensile properties of thin plastic sheeting. For films, foils and other thin flexible plastic materials.

- ASTM D5035 – Standard test method for breaking force and elongation of textile fabrics. Common for woven, knitted or nonwoven fabrics.

- ASTM D792 – Standard test methods for density and specific gravity of plastics by displacement. Calculates properties of polymer materials.

- ASTM D822 – Standard practice for preparing cork composites for test purposes. For testing cork and cork composites.

- ASTM D885 – Standard test method for tensile properties of fiber reinforced plastics. Used for fiber reinforced plastics like composites.

- ASTM D2834 – Standard test method for transition temperatures of fabrics by thermomechanical analysis. Thermal analysis of fabrics.

- ASTM D2240 – Standard test method for rubber property-durometer hardness. For characterizing hardness of rubber materials.

Following standardized protocols ensures consistent testing methods and compatibility/comparison of data globally. Instrument calibration is also against reference standards.

OUR BROCHURE

OUR CATALOG

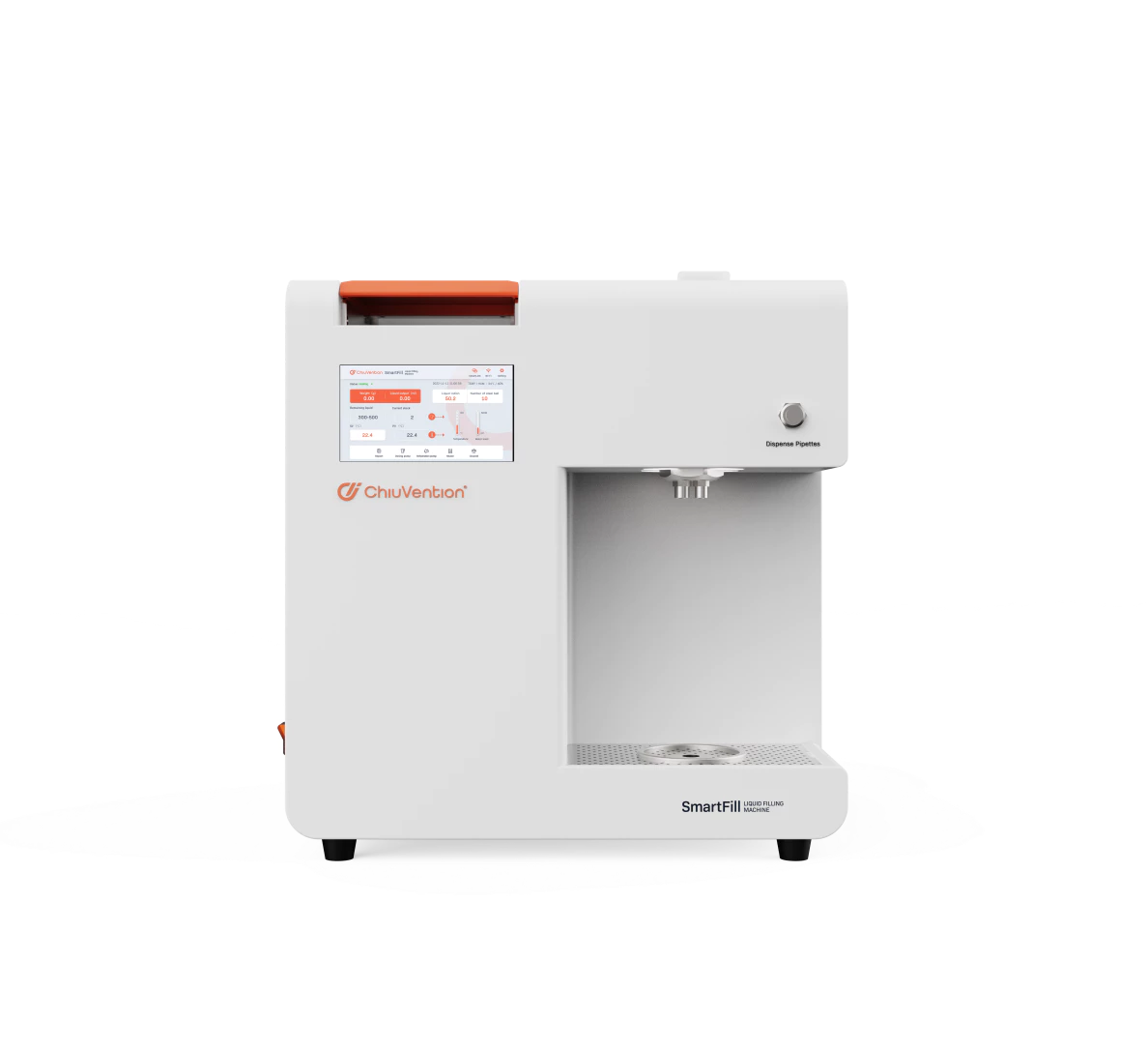

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

_1_.webp)