One-step operation, save time and effort

Sample weighing, soap dispensing according to the bath ratio, steel ball counting, automatic heating and heat preservation, etc, all in one step.

Speed up testing and shorten the order cycle

Improve the washing color fastness test efficiency greatly, to help companies speed up the corresponding order preparation process, higher economic efficiency.

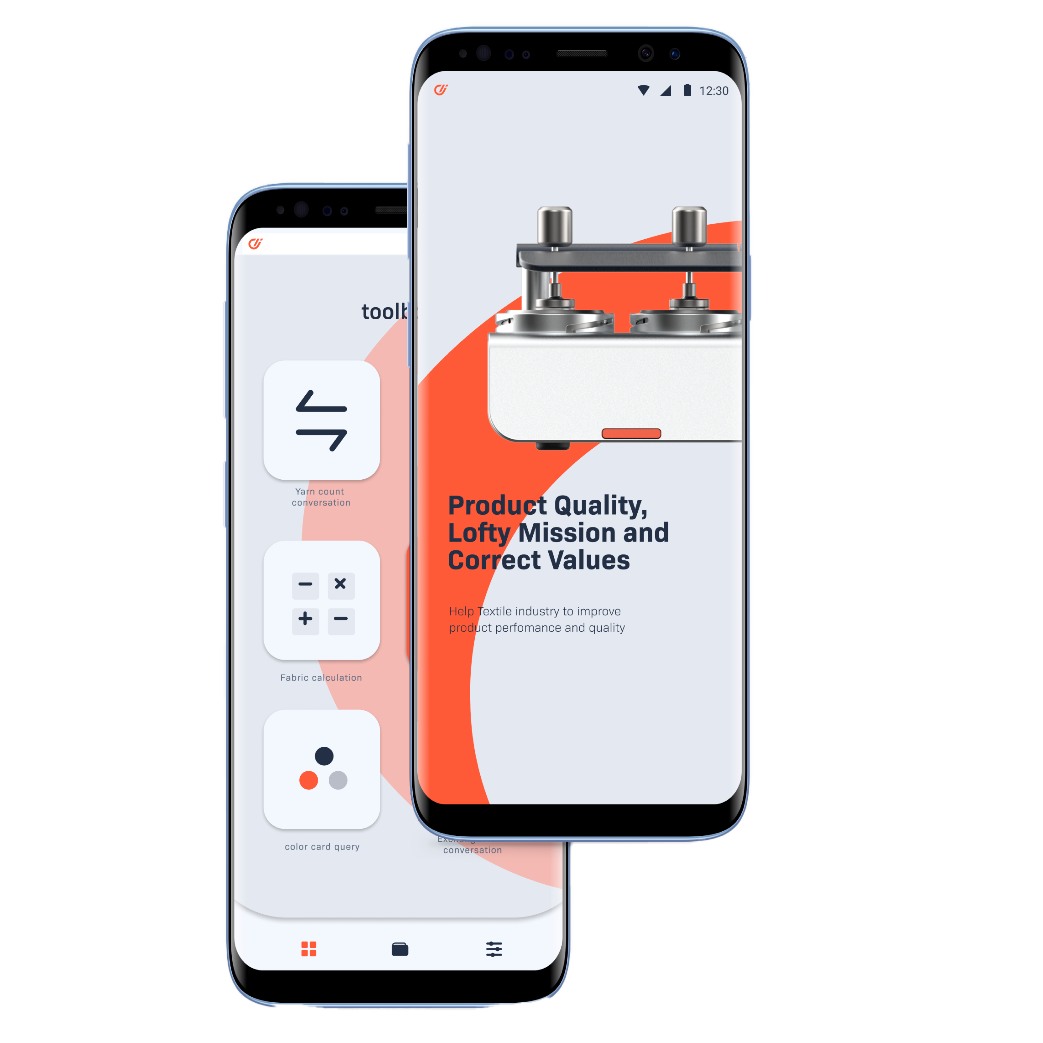

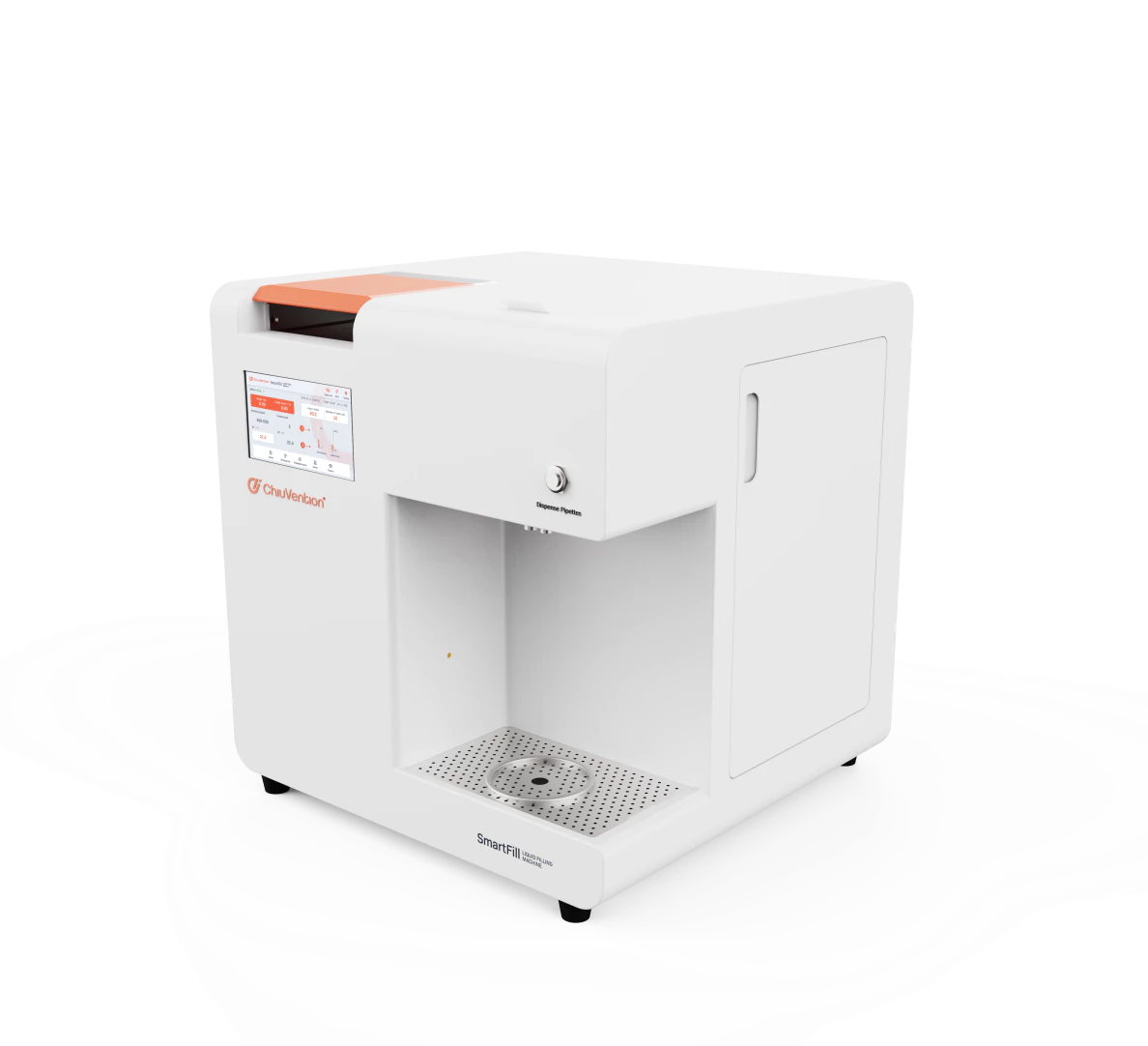

Smart Instrument

Equipped with the Internet of Things, the operator can set the bath ratio and soap temperature on the cell phone and make an appointment to refill the heating. The brand can also monitor and trace the supplier’s laboratory tests online through the cell phone.

Helpful for more accurate testing

A balance of one hundredth high-precision to weigh the sample, the soap is released strictly according to the bath ratio, accurate to 1 ml, a significant increase in accuracy than manual operation, so that each test is accurate and reliable.

Well-known brands are in using

Anta supply chain chose SmartFill, more quickly and efficiently mastered the garment color fastness data, so that corporate brand and quality management became more scientific.

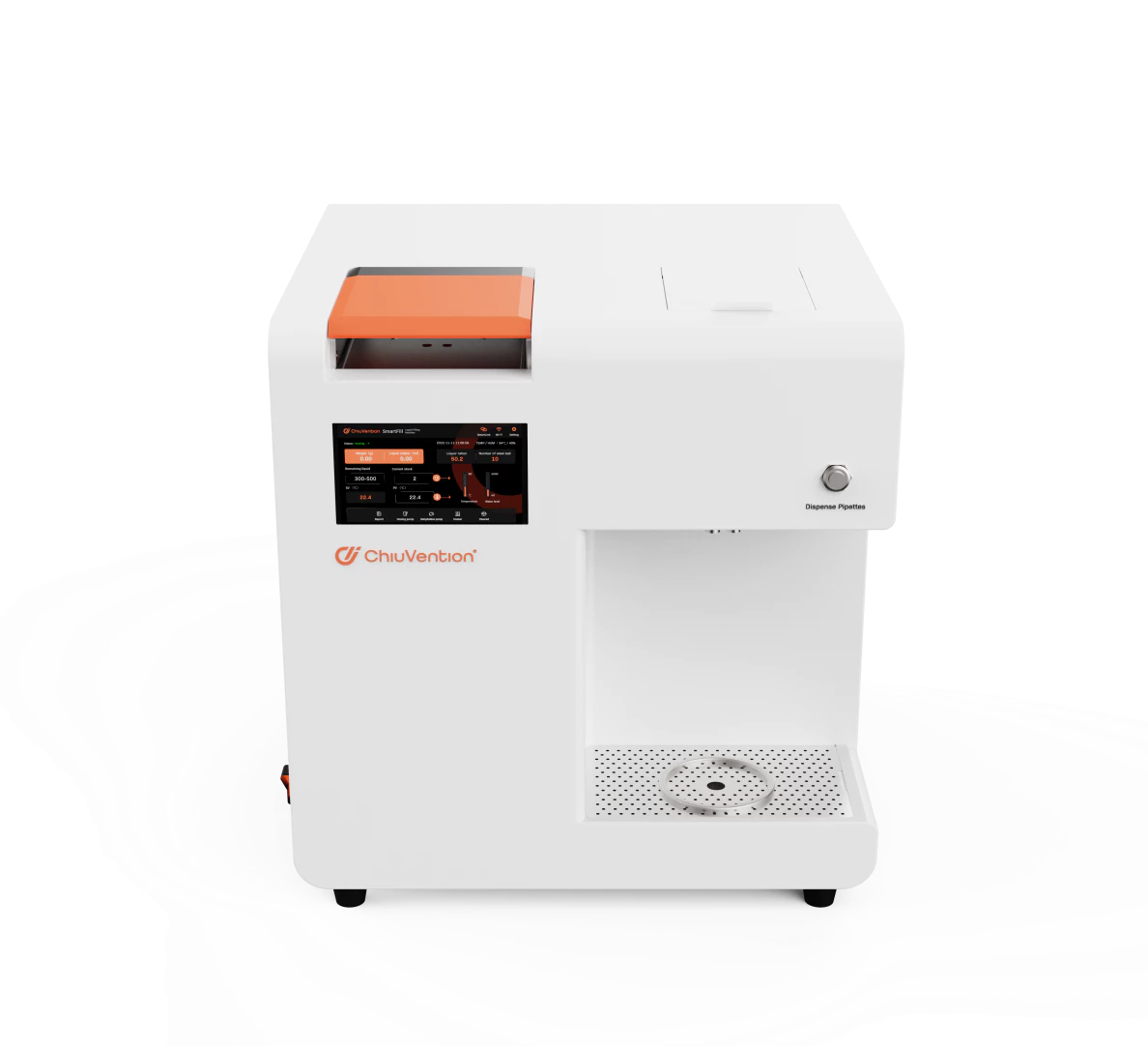

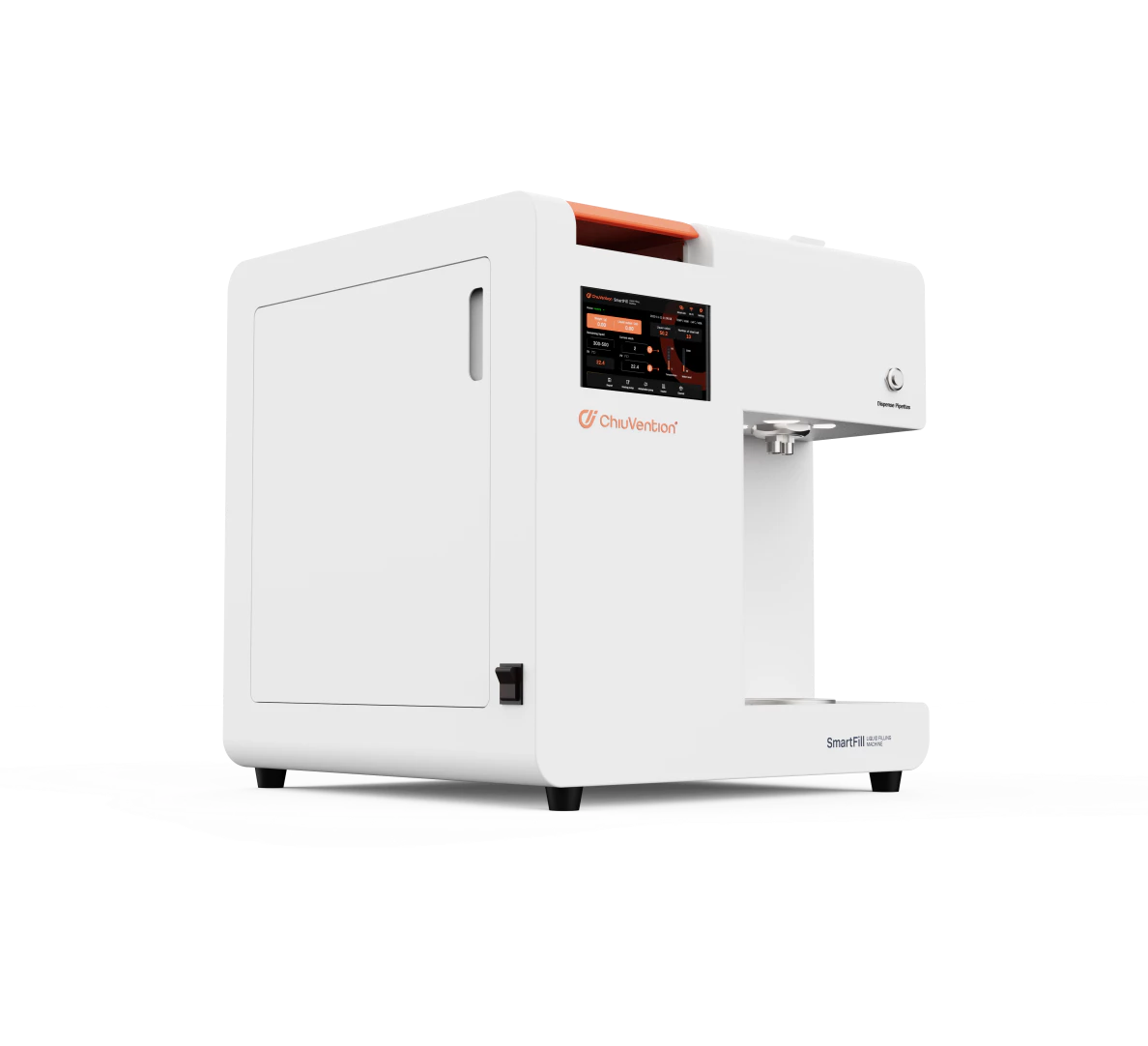

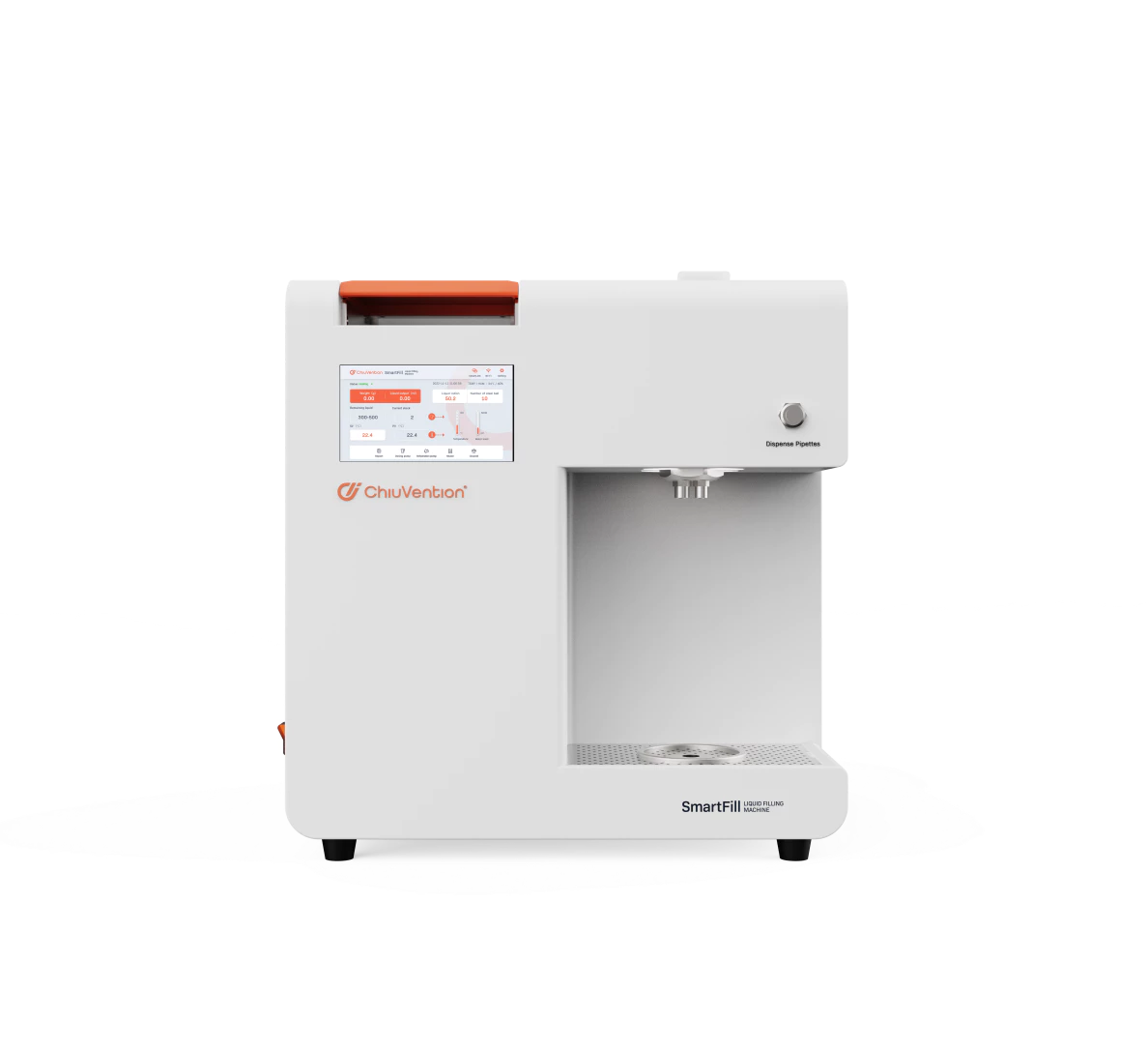

The Specification of SmartFill Liquid Filling Machine

Balance: weighing limit 600g, accuracy ± 0.01g

Soap tank: working volume 6500ml

Soap single pumping volume: 2.5~1000ml,

liquid output accuracy: ±5%

Soap pumping speed: ≤ 28ml / s

Temperature control range: 0~65℃, precision ±1℃

Steel ball filling speed: 10pcs/s

Power AC 230V 50/60Hz 6.5A

Weight 45kg

Dimension 500x500x520mm (L*W*H)

_1_-100x100.webp)

_1_.webp)